How to use Acceptable quality Level AQL

Selasa, 26 Juni 2018

Edit

ACCEPTABLE QUALITY LEVEL

is the "most tolerable" level of the average over

a period of batches. These tables are the United States standard equivalent in

all national and international standardization organizations (ANSI / ASQC Z1.4,

NF06-022, BS 6001, DIN 40080).

Basically, there are three types of defects that are often

differentiated. For most of its restricted goods or products are: Critical l% 0

defect for critical defects is totally unacceptable: users may be harmed, or

rules are not respected The major defect

of 2.5% for major defects of this product is usually not considered to be

acceptable to end-users The minor defect of 4.0% for small defects is some

departure from specs, but most users do not mind The Acceptable Quality Limit,

commonly referred to as an AQL, is a widely used method for measuring sample

production orders to find out whether all product orders have met the client's

specifications. Customers then have data to make informed decisions to accept

or reject them. Your Inspection Report will clearly state whether your

production has passed or failed on your preferred AQL. Note that this tool is

used most during the final outbound inspection when the product is ready to be

sent out and sometimes during production when the number of products is sufficient

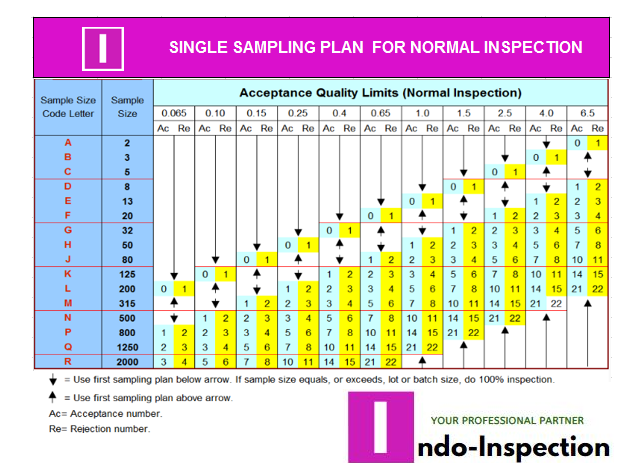

to have an idea of the average quality AQL Tables the AQL table is the buyer

statistics tool (for product inspection). They are industry standards. Most of

the suppliers involved in international trade are already familiar with it AQL

/ acceptable quality level They help determine the two main elements:- How many

samples should be taken and checked, between a set of products or parts of the

quantity order?- Where is the limit

between acceptance and rejection, when it comes to defective products?

The need for objective quality measurement certain product

categories, there will be products that are handicapped almost every

production. Often true even after the manufacturer checks each individual

product and repairs the damaged, since the visual inspection is not 100%

reliable. Therefore, in many supplier / buyer relationships (especially when

the application does not produce live or dead), suppliers are not expected to

deliver flawed goods. The buyer needs to control the quality of the goods /

products purchased, because he does not want too much of the defective item How

to set a limit between acceptance and rejection in a way that can be agreed and

measured?

What the AQL (ACCEPTABLE QUALITY LEVEL) How to

determine the exact sample size and reception number? How to use the AQL table

for correct checks for your needs. For production checks with 4,500 pcs with

Acceptable Quality Limit II, Table A shows the general inspection level

"L". Referring to Table B row L. For sample size 200, with AQL 2.5,

no more than 10 units may fail for forwarded reports

Using the AQL tables, importers should be aware of the

following three parameters:

The lot size – The number of items ordered is the lot size,

and it is advised to perform separate inspections for each lot. If only one

product was ordered, the lot size is the total batch quantity.

The inspection level – Three inspection levels dictate how many samples to inspect:

Level I – This is the least strict inspection level. It can

be used if the importer has a lower tolerance for product quality issues, such

as with lesser-value gifts that come free with a purchase. Or perhaps a

supplier has passed all previous inspections, and the buyer feels confident in

their product quality. It is important to understand that settling for a Level

I inspection as a way to spend less time and money is a high-risk strategy.

Level II – Used by default, Level II is the most widely

adopted.

Level III – The strictest inspection level, Level III

dictates the largest sample size and is, therefore, most representative of the

overall quality of the products. Buyers may opt for a Level III inspection for

high-value products (example: luxury goods)

You May Also Like:

- Step by Step Fabric Inspection

- The Top of Garments Visual Devect

- Soft-Lines and Hard-Line Inspection

- Type of Inspection

- Lashes Pre-shipment Inspection

- How to Rattan Chair processing

- How to Rattan Raw Matrial processing

- How to Know sintetic Rattan

- How to on Site Test of Toys

- How to Inspection Toys Electrics

- Toys Test Performed During Inspection

- Quality Control

- Quality Control Procedure

You May Also Like:

- Step by Step Fabric Inspection

- The Top of Garments Visual Devect

- Soft-Lines and Hard-Line Inspection

- Type of Inspection

- Lashes Pre-shipment Inspection

- How to Rattan Chair processing

- How to Rattan Raw Matrial processing

- How to Know sintetic Rattan

- How to on Site Test of Toys

- How to Inspection Toys Electrics

- Toys Test Performed During Inspection

- Quality Control

- Quality Control Procedure