Process Sewing of Garment

Sewing: Part of the production after cutting process of

manufacturing the garment by combining several panels into a clothing product,

Shirts, skirts, dresses, pants, vest, skirt, jacket or other garment products

that fit Detail specification that has been set with the buyer. Sewing is a

process of the entire garment production process and consists of several

operations Require many employees.

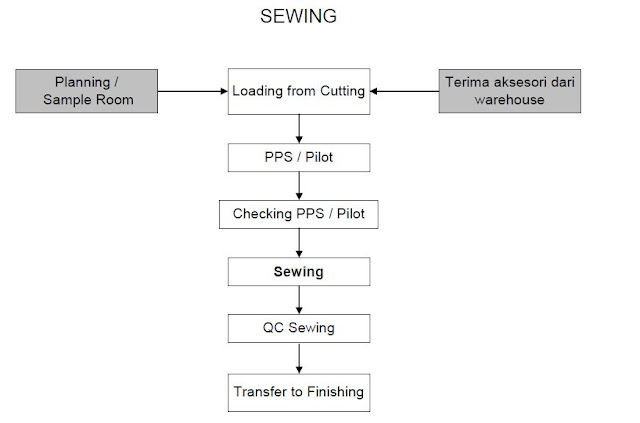

- The process flow in sewing is outlined in the following:

- Sewing works with Planning provides Detail Order (DO) including Comment from the buyer.

- Planning provides material requisition (MR) that contains material that is Needed.

- Planning gives all information from the buyer to the sewing part in the form Comment or additional information about the sample. And samples that have been Approved by the buyer to be a reference for sewing.

- Panel that has been cut and in give fusing in transfer to sewing section and Done per style or per lot to avoid mixing the panel one type of with other types.

- PPS or pilot is an example of garment made by line pilot or supervisor Based on the buyer's approved sample. The purpose of PPS is to find difficulties while sewing, determining time study, Determining the work study, accuracy of size specifications, and as instructions To make a pre lay out machine.

- RPM/Pilot is done by Head Sewing Department, sample Room and QC buyer. Each of these parties provides information process, determining critical processes and providing solutions or work methods The level of difficulty of the product to be made.

Industrial Engineering Department will be involved in the

process by Give an overview of the results of time study and method study and layout

the machine. After all the processes are passed, the sewing manager will The

mass production process immediately began.

What makes special sewing clothing is a small and unique

detail. From stitched buttonholes is perfect to apply topstitch like an expert.

In this article, you'll find some great ideas for making the most of your

outfit – sewing.

A. Use Sewing Machine for Stitch the Buttonholes precisely.

Measure your buttons. Add 1/4 "and set the arrows on

the Buttonhole legs with a slide for the long one. Before placing the spindle,

placing the spindle yarn through a small hole in the finger of the bobbin

casing. Then load it up on the machine as usual. This will tighten the tension

of the bobbin yarn and give the yarn over a more rounded appearance on the

right side of the fabric.

Thread the top of the machine and attach the Buttonhole

legs. It is a good idea to test the size of the studs before stitching your

garment. So, grab a piece of cloth and position it under the Presser feet with

the top of the buttonholes positioned beneath the needle.

Set your machine to stitch the studs. Stop the stitches and

press the reverse button once to let the machine know you have reached the

desired length. When the studs are done, the needle rises and the center itself

is above the buttonhole tip.

Thoroughly cut the buttonholes and test your buttons. If it

fits well, then you are ready to start stitching the rest of the buttonholes on

your garment.

B. Insert Open zipper easily

Before attaching an open zipper, we will sew the stay into

the zipper opening. Cut the live using a strong woven cloth that is 3 1/4 "(8 cm) wide and 2 1/2 " (6 cm) longer

than the zipper opening.

Using a pen or pencil, mark unzipped on the garment and

stay the same with half the width zipper ribbon plus 5/8 "(1.5 cm), which account for stitching

allowance above. If your seam ration is different (i.e., 1/4 "or 1/2 "), mark it accordingly.

Match the rectangular sign on the clothes and stay and the

baste machine together.

Cut the center to about 1/2

"Above the end, then cut diagonally into the corners. Be careful

not to cut through stitches!

Turn stay inside and press, making sure that the rolls stay

into just a little bit.

The bottom zipper center opens with the bottom of the

zipper stop flush against the bottom end of the opening. Slip Stitch in place.

Lift the bottom of the garment to expose the tip of the

zipper ribbon and the cloth triangle underneath.

After, fold back one side of the garment and start from

underneath, sewing the garment to the zipper ribbon along the Olesi line.

Repeat on the other side. To finish, remove the grease and lightly press on the

right side.

C. Top Stitch like a professional

There are some tips that can up your jewelry game. With

proper planning and some clever, professional secrets, anyone can have a pretty

topstitch every time. Follow these tips to set up your topstitch.

- Plan, before you sew,

- Know your thread selection,

- Choose the right Stitch,

- Choose a sharper needle,

- Always use the guidelines,

- Glue cloth is your best friend.

- Beautiful stitches to hold it all together

- Making beautiful stitches can be a challenge if your sewing machine is not set up properly. Follow these simple steps to set it up.

Flow Chart sewing:

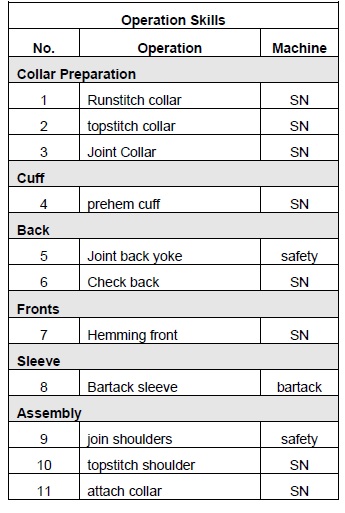

Operator Ability Mapping such as in the table below the

operation of the sewing

Operation Skill Assessment:

You May Also Like:

- How to use Acceptable Quality Level (AQL)

- Container Loading Check

- Carton Drop Test Check

- Electronics Inspection

- During Furniture Inspection

- During Hard-Lines Inspection

- Preshipment Inspection Furniture

- Furniture and Rattan Inspection

- How to Step use Moisture Content (MC)

- How to check Moisture Content (MC) wood

- Pre-Shipment Inspection Hardlines and Softlines

Belum ada Komentar untuk "Process Sewing of Garment"

Posting Komentar