The Top of Garments Visual Defect

1. UNTRIMMED THREADS: Usually most are found when manufacturers rushed and they

did not take the time to cut because of the pursuit of the target and the

delivery time or on the end line many were missed by the yarn cutter section

and at their internal QC inspection. An uncut thread is generally considered a minor defect; but

they can be a more serious problem if there is a large amount moreover the

thread length is more than 1/2 inch and can be a major defect

many buyers assume

that uncut yarn makes clothes look "cheap" because it is a sign of

poor workmanship. In baby clothes is very serious because it involves safety

and depends on the location of the thread that is not cut, it can be dangerous.

If the thread is caught around their fingers or toes, it can cause serious

damage due to their delicate skin

Causes and solutions: An uncut thread is one of the easiest defects to repair.

Clothing manufacturers need to be more vigilant when cutting any excess thread

before goods are packaged and shipped. End line, QC. finishing should check

carefully if you find the remaining threads of QC. End line, QC. finishing must

be collected and returned to the thread cutter before packing and shipping

2. BROKEN OR SKIPPED STITCHING: usually an error in poor sewing machine settings, the

quality of the thread used, or workers who lack mastery, this is a visual

problem of major defects, especially for clothing that has contrast stitching,

such as jeans. Stitching problems can also weaken the structural integrity of

the stitches, causing poor product quality or even open seam and impacting the

buyer

Causes and solutions: Damaged stitches can be caused by rough handling or poor

yarn quality. If there are stitches that are skipped, the worker may hurry, the

sewing machine might not be installed correctly, or the machine is inadequate

for the fabric, you should call a mechanic and reset it immediately so that the

sewing machine becomes good, Sewing problems are generally considered a minor defect,

but can be large if the problem is proven at a high percentage of orders or in

highly visible garment areas.

If broken or skipped seams are found during garment

inspection, this needs to be taken care of by the supplier. The manufacturer

may be able to repair it in a reasonable time if the goods have not been sent.

If the goods have been sent, you must reach an agreement with the manufacturer.

You May Also Like:

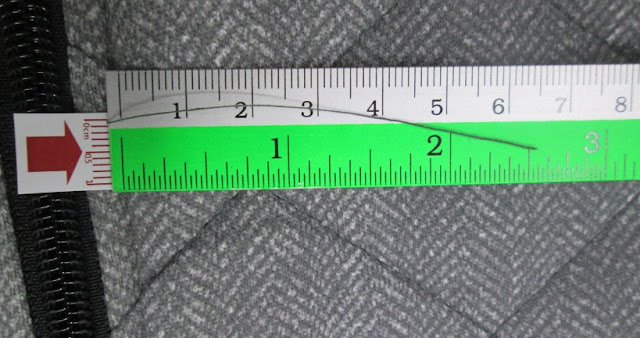

- Calibration Garment tape measurement

- During Production Inspection

- Top Garments defect

- Garments Pre-shipment Inspection

- How to Process Cutting on Garments

- How to Measure of Garments

- Needle Detector

- Process Sewing of Garments

- How to Process Washing Denim

- Quality Control Garments System

- Soft-Lines Pre-shipment Inspection

- Step how to setting QC and QA Garments

Belum ada Komentar untuk "The Top of Garments Visual Defect"

Posting Komentar