Furniture and Rattan Inspection

Teak furniture and rattan furniture, bamboo furniture and

other handmade furniture have been greatly admired by furniture lovers all over

the world. Therefore, the demand for furniture is still a lot in the market and

high in quality, even though there are bad services provided by some furniture

exporters, there are still many good and reliable furniture manufacturers.

Therefore, choosing the right supplier will certainly pay for your investment

in buying furniture.

Furniture and rattan design continue to evolve to meet

modern designs and fashion trends, this presents a significant challenge of

quality, safety and durability for manufacturers in general. To verify these

attributes in furniture, raw materials and manufacture throughout the supply

chain, we will offer a range of furniture inspection services from

pre-production to the end of production and loading, Quality control of

furniture products requires sufficient experience and understanding of the

details of the process, Technical inspection adjusts our standard Product

Checklist by adding special tests to meet your quality requirements.

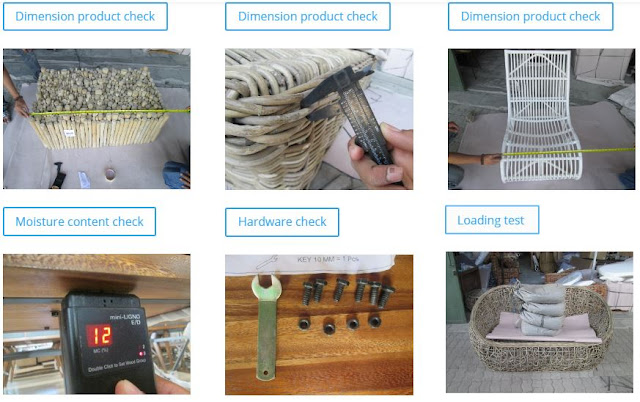

Tests Performed during Furniture and Rattan Inspection

- Rub test

- Smell check

- Assembly check

- Sharp edge check.

- Wheels function check.

- Weight check.

- Measurement check.

- Bar-code scanning.

- Moisture content check

- Carton drop test.

- Function test.

- Color shading check.

- Symmetry check.

- Carton drop test

- Loading test.

INSPECTION FURNITURE INDUSTRY.: This procedure is made with the aim to standardize the

implementation of inspections or checks in accordance with the requirements of

the customer or buyer. The procedure is also made to give a sense of customer

satisfaction and satisfaction.

With this procedure, we will be able to explain matters

relating to inspections that lead to better production results. This

responsibility is given to quality control / QC in particular and production in

general.

The procedures include:

1. The Quality Control Division carries out product

inspection with the following conditions;

- Wood quality: check humidity, uniformity, type of wood (eucalyptus, oil groove and eye wood type)

- Construction: Form construction, neatness, cleanliness, assembling systems and others.

- Dimensions: General size and detail according to patron or sample.

- Finishing: the results of sandpaper, finishing, smoothness, cleanliness, beauty, and color.

- Spare parts: Brass, wood and other accessories spare parts.

- Final check: Check all wood, construction, finishing, assembling instructions, packing

- Packaging: Print on the box, size, image, packaging method and accessories.

2. The quality control section gives the status of

inspection whether the product is ok or not or with other requirements for

further processing information.

3. The quality control section records the results of

inspections that have been carried out by marking or signing as accountability.

4. The quality control section reports to the supervisor on

the results of the inspection.

That is the procedure that must be carried out in the

inspection in the wood industry by not forgetting the appropriate form, whether

it is an inspection card or the results of the inspection. All conditions are

where we work, which of course we take these procedures in general.

Finishing area

Finishing area

- Step by Step Fabric Inspection

- The Top of Garments Visual Devect

- Soft-Lines and Hard-Line Inspection

- Type of Inspection

- Lashes Pre-shipment Inspection

- How to Rattan Chair processing

- How to Rattan Raw Matrial processing

- How to Know sintetic Rattan

- How to on Site Test of Toys

- How to Inspection Toys Electrics

- Toys Test Performed During Inspection

- Quality Control

- Quality Control Procedure

Belum ada Komentar untuk "Furniture and Rattan Inspection"

Posting Komentar