Top Garments Defect

Before starting to check over a garment, we need to remark what is a defect. We must also evaluate it depending on the type of defect and its position on the garment. In order to do this, it is necessary to have a Garment Defect Classification document. However, how do you decide what is a defect and the level of it? What guideline should the inspector follow to consider a defect? The purchasing company is who determinates the list of defects and their importance. Either in a specific document (Classification of Garment Defects) or including it in the Quality Manual.

Classification of Garment Defects consists of:

A list of defects: The list of all the penalized defects and

their importance according to the area where it is located.

Illustrative photographs of the defects.

Graphics identifying the importance of the garment areas.

The defects list: The defects list contains all the defects

that may occur during garments production. In addition to each defect is

assigned its level of importance depending on the position in which it is

located

This means that the same defect would be more or less

important, depending on how visible it is on the garment. The level of

importance is established in three categories: CRITICAL, MAJOR or MINOR.

Defect Critical: The product condition found which poses the

possibility of causing injury or harm tor otherwise endangering the life or

safety of, the end user of the product or others in the immediate vicinity of

its use.

Defect Major:

The product condition found adversely

affecting the product’s marketability and sale-ability or adversely affecting

its required form, fit, or function, and which is likely to result in the end

user returning it to the source from which it was purchased for replacement or

refund. Factory workers may be able to reasonably repair or rework the

defective garments. Other times, the factory cannot easily remedy major

defects, and the importer may ask their supplier to cover the loss or

manufacture replacement pieces. Some brands may also accept imperfect garments

and offer discounts through special distribution channels, such as factory

outlet stores and other retailers.

An example of major defects you may find in garments is

incorrect colors or designs on the product. These are sometimes acceptable when

the garments still have proper dimensions. While using the wrong colors or

designs is not desirable, the clothes can usually be sold if they’re still

proportionate and match standard size categories (e.g. S, M, L and XL). Issues

with sizing out of tolerances or incorrect stitching are often considered major

defects that would result in the importer rejecting an order of garments. If

the clothes don’t fit correctly or tear or fall apart easily, these products

are likely to be returned by customers and tarnish the image of the brand on

the label.

Defect Minor: The product condition found which while

possibly less than desirable to the end user of the product, does not adversely

affect its required marketability, sale-ability, form, fit, or function and is

unlikely to result in its return to the source from which it was purchased.

Open Seams: The problem with open seams is usually that it’s

not eyes appealing because it looks sloppy, chances are all the seams will

continue opening one at a time causing the item to fall apart. Sewing is a

difficult process. Whether it is hand performed or done by a sewing machine, it

still requires a very thorough attention to detail.

Unsecured Seams: Unsecured seams might not always be

noticed, especially when purchasing the clothing item. However, as some of the

other above-mentioned flaws, this can also cause the item to fall apart later.

It can lead to defects like open seams, which are in no way eye appealing and

are a sign of poor quality.

Joining Defects: Joint defects, in their turn, are probably

one of the major and more visible defects that can catch the eye. Joint defects

are the mismatch of the fabric pieces that are attached by stitches. This is

especially noticed if the colors of fabric differ. Joint out defects are a

result of poor handling. Be that inattention to the sewing process or any other

detail, the result is definitely not one to please.

Button Defects: This is again, one of those commonly seen

faults. They are considered to be garment defects which include loose buttons

or uneven button holes. It’s not a difficult process to cut open a millimeter

of fabric to help the button slide into it. Neither it is difficult to secure

the button stitches yourself. But the industry itself should be responsible for

those types of minor flaws.

Defected Stitches: Sometimes we notice missing stitches on

things we just recently bought or were close to buying. This is one of the most

commonly met faults that a garment product can have. Sometimes, you wouldn’t be

able to tell that there is a skipped stitching. However, on jeans or other

clothing items that have different color stitches, the defect would be more

visible. Problems like this can occur because of a rush or a bad working

machine. If the factory workers hurry to complete the hand sewed item in a fast

manner, such defects can become unavoidable. They can also cause the clothing

piece to fall apart, in the worst-case scenario, depending on what kind of item

it is and what material it is made of. However, they can still be fixed if the

factory is careful enough during the quality inspection stage of production

before the product gets to the consumers.

Untrimmed Threads: This is one of the most commonly seen

defects that are possible in the apparel industry. They are also one of the

easiest ones to deal with. Even if you as a customer bought a piece with an

excess 2 cm thread, “it’s not a big deal” you might think and cut it later

yourself. However, any kind of defect is better when it is avoided. In the same

manner, untrimmed threads can and should be detected during the QA process.

Still, they don’t have the same impact and do not seem to make the same

impression on a buyer depending on where they are exactly located. If the

excess thread is on the inside of the clothing item, sometimes they will not be

even paid attention to. But in any case, it is safe to thoroughly check every

part of the item before you are sure it can be sent to the market. Being one of

the most easily noticed and easily solved defects, the extra centimeter of a

thread can gives your appearance a “sloppy” look.

Puckering Defects: Met a lot, solved rarely. Puckered

surrounding of stitches on the fabric are no rare occasion, unfortunately. They

are also hard to fix because they require the entire stitching process to be

done again. This in its turn can cause needle holes as left marks. Puckering

defects can occur because of rough handling with the fabric, inattention

towards the sewing process or because of the machine itself. Whichever the

reason is, attention to detail and careful handling towards the fabric is probably

the best way to avoid such defects from happening.

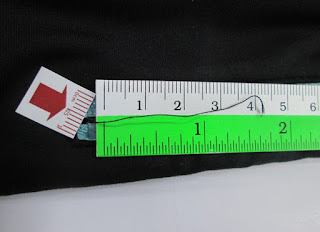

UNCUT TRIM

UNCUT TRIM

BROKEN STITCH

SKIP STITCH

UNCUT TRIM

You May Also Like:

- How to use Acceptable Quality Level (AQL)

- Container Loading Check

- Carton Drop Test Check

- Electronics Inspection

- During Furniture Inspection

- During Hard-Lines Inspection

- Preshipment Inspection Furniture

- Furniture and Rattan Inspection

- How to Step use Moisture Content (MC)

- How to check Moisture Content (MC) wood

- Pre-Shipment Inspection Hardlines and Softlines

Belum ada Komentar untuk "Top Garments Defect"

Posting Komentar