Furniture Process Inspection

Surely you are already familiar with furniture, right? One

of them is what material will be used to make the furniture. For the

manufacture of furniture generally use wood materials. And of course, this wood

has many types also starting from teak, mahogany and many others. Furthermore,

consumers must also pay close attention to the type of furniture which will be

chosen. Furniture factories can make a variety of furniture according to the

desires and needs of consumers. Ranging from cabinets, shelves, chairs and many

others. If you visit the location of a furniture company in Jakarta you can

certainly see how the production process is. Maybe for you it looks simply, but

it should be well known that the process of making this furniture is not easy

at all. Only people from experienced furniture factories can produce furniture

according to customer demand. Therefore, as a good consumer, it would be better

if you could choose the best and most experienced furniture manufacturing

factory. The entire production process carried out by furniture companies

varies in importance. And this is the production process.

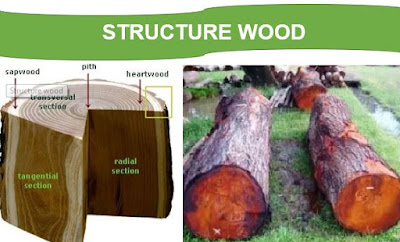

A. Logs Process: Wood that is still round with a diameter

between 25-28 cm (depending on the type of wood used) has not gone through any

process. Except actions to prevent cracking at the end of the log. The logs are

then sawed to get boards and beams as needed.

B. Sawmills Process: Next is the cleavage of logs so that

they can be dried easily using a wood dryer. This furniture factory will cut

wood according to the size of the wood dryer room and furniture ordered by

consumers.

C. Drying wood Process: After being cut into pieces, the

wood will be dried. Because if it is not dried, then the wood can change shape

depending on the moisture content in the wood. For the method of drying wood

carried out by this Jakarta furniture factory also varies. But still has its

own drying.

D. Basic defense Process: The ideal wood for chopping and cutting

is when it is dry. This process was carried out in the detention room. In this

process we must really know the exact size of the components for furniture. So

that the Wood fiber settings according to the position of components can be set

correctly. In addition, furniture companies also conduct wood quality checks to

determine the natural defects of wood.

E. Construction Process:

Starting from dragging wood to produce a smooth surface, then cutting

the long side as a finished size. Until the construction of holes is the

longest process carried out by a furniture factory. Some parts of furniture

often go through the same process repeatedly. For the construction process is

making dowel holes, making tenons and mortise. Next groove & notch,

hips at the tips of the wood and many others.

F. Sanding Process:

If the furniture factory is finished making construction, then the next is to

do sanding. In this process using sandpaper grit and done in stages. Of course,

at this stage there should be no such thing as broken, cracked or discolored

wood. Because this should have been done during the construction process standards.

J. Installation of equipment Process: The equipment in

question is in the form of hinges, locks and handles. Furniture manufacturers

will usually do this installation after the finishing process is complete. This

is done to maintain the quality of the material for the better. Before doing

the finishing process it would be better if covered with plastic when

finishing.

H. Assembling Process: In this process, it is certainly

adjusted to the furniture you ordered. If you order knock-down or removable

furniture, the assembly can be done after finishing. In contrast to the door or

drawer, of course it needs to be assembled in advance by the furniture company

If all the parts that need to be assembled are set properly. Then the sanding

process can be continued after finishing.

I. Finishing Process: All wood defects or construction

errors should have been done by the furniture factory when entering this stage.

Finishing becomes the last thing in the process of making furniture. By doing

this finishing course will make furniture more attractive and beautiful of

course.

You May Also Like:

- Calibration Garment tape measurement

- During Production Inspection

- Top Garments defect

- Garments Pre-shipment Inspection

- How to Process Cutting on Garments

- How to Measure of Garments

- Needle Detector

- Process Sewing of Garments

- How to Process Washing Denim

- Quality Control Garments System

- Soft-Lines Pre-shipment Inspection

- Step how to setting QC and QA Garments

Belum ada Komentar untuk "Furniture Process Inspection"

Posting Komentar