Electronics Inspection

How to check Electrical & Electronics

Increasingly advanced technology E & E market is

growing fast, and yet setting increasingly high expectations for quality,

performance and reliability. Our knowledge and capability assist importers to

ensure consistent quality and safety across a complex supply chain.

- Mobile Phones

- Household appliances

- Wearable device

- Audio

- Lighting

- Electrical tools

- Modem

- Iron Steam

Factories in general use shortcuts and new technologies (not

fully tested) to fulfill clients’ regular needs for innovation and energy friendly

products in shorter lead time. A proactive strategy for household appliances

quality control and safety is crucial to making sure only high-quality products

are manufactured by these factories. Our expertise includes product categories

such as kitchenware, personal care products, and other appliances.

verifies the quality, specifications, functions, and safety

of your household appliances and compliance of your household products with

relevant international standards.

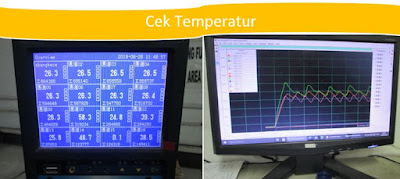

ELECTRIC SAFETY TESTS AND FUNCTIONALITY

- Ground Continuity test failed

- Dielectric Strength test failed

- Input power out of range

- When the appliance is plugged, the red light does not turn ON

- Incorrect functionality of thermostat and/or not smoothing rotation

- Heating time too long; green light does not turn on when ready

- Plates temperature out of allowed range

ELECTRIC PARTS & INSIDE INSPECTION

- Not all components comply with Bill of material

- Supply cord is damaged or wires are visible

- Internal fast-on connectors are not perfectly fixed

- Some components are damaged

- Loose parts inside the appliance

- Ground connection not properly done

The Construction is essential for electronic and electrical

products, it can detect non-conformance from general electrical safety, it can

detect deviation between many products for sample certification/Sample testing.

The Points but are not limited to, covered by the service

- Marking Verification

- Verification of internal and external wires

- Resistance to electrical power test

- Continuity Endurance tests. Earth

- Earth Terminal Verification

- Verification of clearance and propagate distances

The important inspections when performing inspection:

- contract quantities

- the packing way and related labels

- storage way of your products

- inspection workmanship appearance

- inspection function, size and measurement

- inspection reliability and safety tests

- inspection related shipping files

- inspection other specified requirements client.

You May Also Like:

- Calibration Garment tape measurement

- During Production Inspection

- Top Garments defect

- Garments Pre-shipment Inspection

- How to Process Cutting on Garments

- How to Measure of Garments

- Needle Detector

- Process Sewing of Garments

- How to Process Washing Denim

- Quality Control Garments System

- Soft-Lines Pre-shipment Inspection

- Step how to setting QC and QA Garments

Belum ada Komentar untuk "Electronics Inspection"

Posting Komentar